We Maintain Lifts with Accuracy: Ensuring Security and Performance

We Maintain Lifts with Accuracy: Ensuring Security and Performance

Blog Article

Exploring the World of Elevators: Typical Issues Encountered by Various Lift Mechanisms

As we navigate through the vertical transportation systems of modern-day buildings, elevators stand out as a crucial component of our everyday lives. From hydraulic elevators to grip systems and machine-room-less layouts, each lift type comes with its collection of usual concerns.

Hydraulic Elevators

Hydraulic lifts, frequently liked for low-rise structures, make use of fluid stress to control the movement of the elevator automobile (lift repair companies). This device entails a hydraulic pump pressing oil right into a cylinder, causing the elevator to relocate the wanted instructions. While hydraulic lifts are recognized for their quiet and smooth operation, they do come with their own collection of usual concerns

One widespread trouble with hydraulic lifts is oil leak. The seals in the hydraulic system can break with time, bring about oil infiltration. This not just develops a mess yet can additionally influence the elevator's performance if left unaddressed. Additionally, problems with the control system, such as faulty valves or a malfunctioning pump, can trigger interruptions in the elevator's motion.

Regular maintenance and punctual repair services are vital to guarantee the smooth functioning of hydraulic lifts. By attending to these typical issues proactively, structure proprietors can reduce downtime and guarantee the safety and performance of their upright transportation system.

Grip Elevators

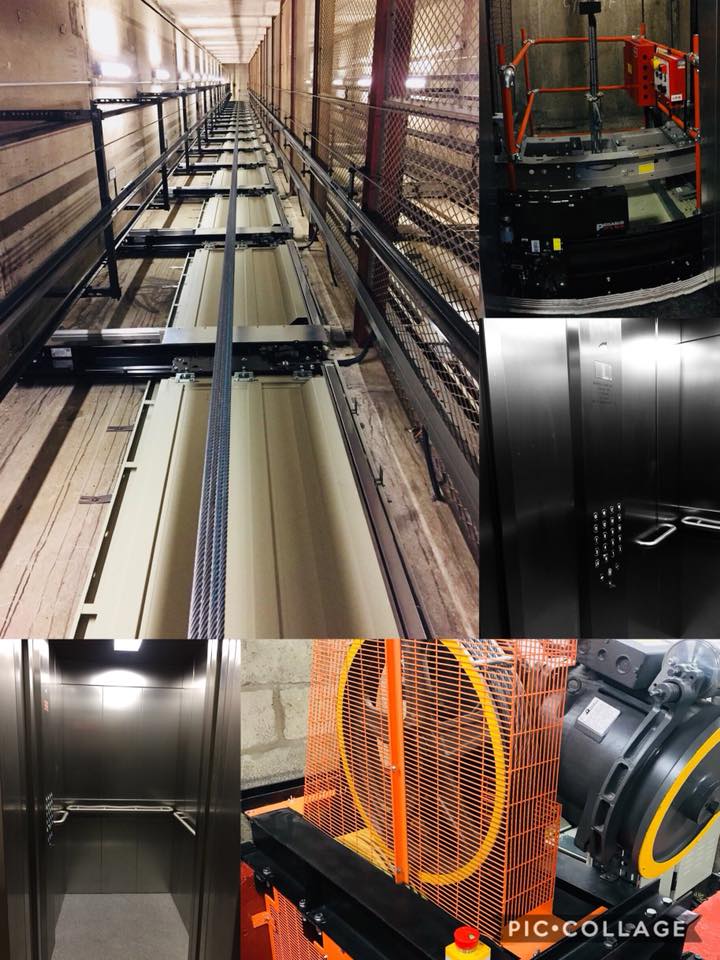

When considering upright transport systems in buildings, an additional typical kind in addition to hydraulic elevators is the grip elevator. Grip elevators run utilizing a system of ropes and counterweights that relocate the elevator automobile by grasping onto the hoist ropes. This device enables smoother and faster upright transportation contrasted to hydraulic systems.

One of the usual problems encountered by traction lifts is rope wear. The constant activity of the ropes within the grip system can lead to deterioration with time, potentially creating the elevator to breakdown or come to be harmful for use. Normal evaluations and upkeep of the ropes are important to make certain the elevator's appropriate functioning and safety.

An additional issue that grip lifts may come across is associated with the control system. Issues with the control system can bring about problems such as unpredictable motion, hold-ups in reaction times, or even full shutdowns. Routine screening and upkeep of the control system are important to stop such issues and make sure the lift's reliability.

Machine-Room-Less (MRL) Elevators

One of the vital elements of MRL lifts is the compact gearless traction machine that is installed within the hoistway. This maker efficiently drives the lift cars and truck without the need for large equipment located in conventional grip elevators. In addition, MRL elevators commonly utilize a weight system to balance the auto, additional boosting their energy performance.

In spite of their benefits, MRL elevators may deal with obstacles related to maintenance and repair service More about the author as a result of the confined room for equipment installation. Accessibility for servicing parts within the shaft can be limited, requiring specialized training for service technicians. Appropriate upkeep schedules and regular evaluations are vital to my website make certain the ongoing smooth procedure of MRL lifts.

Overloading and Weight Limit Issues

Straining and weight restriction problems are vital issues in lift operations. Elevator makers layout lifts with particular weight capacities to make certain guest safety and security and devices longevity.

When lifts are overwhelmed, it puts excessive pressure on the motor, cords, and various other components, possibly triggering malfunctions or breakdowns. If they spot excess weight, safety and security systems such as sensors and overload sensing units are in place to protect against elevators from relocating. Furthermore, going beyond weight limits can bring about boosted energy usage and wear and tear on the elevator system.

To minimize overwhelming concerns, constructing managers must prominently show weight limits in elevators and enlighten residents on the relevance of adhering to these constraints - lift repair companies. Routine upkeep checks by certified service technicians can additionally help make sure that lifts are running within secure weight parameters. By attending to overloading and weight limit issues proactively, structure proprietors can enhance elevator security and effectiveness

Electric System Failings

Surpassing weight limitations in elevators can not only lead to mechanical issues yet additionally possibly add to electric system failings within the lift framework. Electrical system failures are an important problem in elevator operation, as they can cause unanticipated closures, breakdowns, or even security dangers.

In addition, power rises or changes in the electrical supply can also interfere with the lift's operation, influencing its performance and safety. These electrical disturbances can harm sensitive elevator parts such as control board, circuit boards, or sensing units, causing system failures. Regular upkeep and evaluations are vital to determine and address prospective electrical concerns immediately, ensuring the secure and effective operation of lift systems. By adhering to weight limits and performing routine electric system checks, building proprietors can mitigate the danger of electrical failings in elevators.

Final Thought

Hydraulic lifts, often chosen for low-rise structures, utilize fluid stress to control the activity of the elevator vehicle.When considering upright transportation systems in buildings, an additional typical type apart from hydraulic elevators is the grip lift. Traction lifts run utilizing a system of ropes and weights that move the elevator cars and truck by gripping onto the hoist ropes. Unlike typical elevators that need a different machine space to house the tools, MRL elevators integrate many of the elements within the shaft, eliminating the need for a committed machine space.In verdict, lifts face typical problems such as hydraulic malfunctions, grip system failings, and electric system problems.

Report this page